DESIGNLOGIQ Gets Great Response at 2023 World of Modular

- STAFF

- May 16, 2023

- 3 min read

Updated: Aug 26, 2024

DESIGNLOGIQ’s debut at the World of Modular was a major success! Architects, owners, developers, construction managers, dealers, and others in the modular world were excited to hear about the unique value we can bring to their projects. Some of the comments we heard:

“It’s about time somebody’s put design for modular first instead of treating it as an afterthought.”

“We’ve been looking for a design partner who understands the manufacturing and construction aspect. We need to know if our conceptual designs can be efficiently turned into modular buildings.”

“Having access to an expert modular design resource—especially for the technical aspects of modular projects—will take a lot of pressure off our own design team.”

“Design services that make modular projects more streamlined, more buildable, more functional, or more beautiful means more modular projects will be built. And that’s great for the modular industry as a whole.”

We did run into some questions that we thought might be helpful to answer…

Q. What’s your relationship with your sister company? Do you design only for MODLOGIQ?

A. Not at all. DESIGNLOGIQ is 100% vendor neutral. Our plans will allow you to work with multiple qualified modular manufacturers and enable them to price, source, and execute your project. Yes, the manufacturing and construction experience we’ve gained from delivering hundreds of successful modular projects at MODLOGIQ does inform our ground-breaking Design for Manufacturing, Assembly + Construction methodology (see DMMA+C below). But our first and only mission is to develop and execute a modular design that is best suited to cost-effectively turn your vision into a successful modular project. We believe this will solve a number of issues we see limiting modular projects:

Comparing apples to oranges. Many modular manufacturers will often have proprietary construction methods, custom materials, varying engineering specs, etc. for the same job. This makes it difficult to evaluate various proposals. It also results in wildly divergent pricing (we’ve seen responses to the same RFP range from $190/SF to $800/SF). DESIGNLOGIQ eliminates this confusion and complexity. Our single, defined scope of work and set of plans will enable you to compare apples to apples across multiple manufacturers.

Inappropriate design/specs for the project type/regulatory regime. We see this most frequently in healthcare and education projects, where one manufacturer will quote to a spec that ultimately won’t pass muster with the agency having jurisdiction. Or they’ll limit design options with little or no flexibility for customization. For those new to modular construction, getting diverted by these kinds of detours can result in frustrating dead ends, schedule delays, and added costs.

Q. Do you also negotiate manufacturing contracts?

A. We do not. We provide professional services and will gladly collaborate with your modular manufacturer, construction manager/general contractor, consultant, and/or internal construction team. But we don’t undertake contract administration, review, or selection.

Q. Do you offer modular design services for multi-family housing?

A. We offer design services for virtually any type of modular project, including multi-family housing. Further, the efficiencies possible with light gauge steel prefab wall, joist, truss systems and other prefabricated components makes DESIGNLOGIQ the ideal partner to optimize the budget and schedule of multi-family projects. That said, we find our greatest value-add is with complex permanent modular projects in healthcare, higher ed, K-12, retail, commercial, and student housing. The best way to find out how we can add value to your project is to contact us to discuss your specific needs.

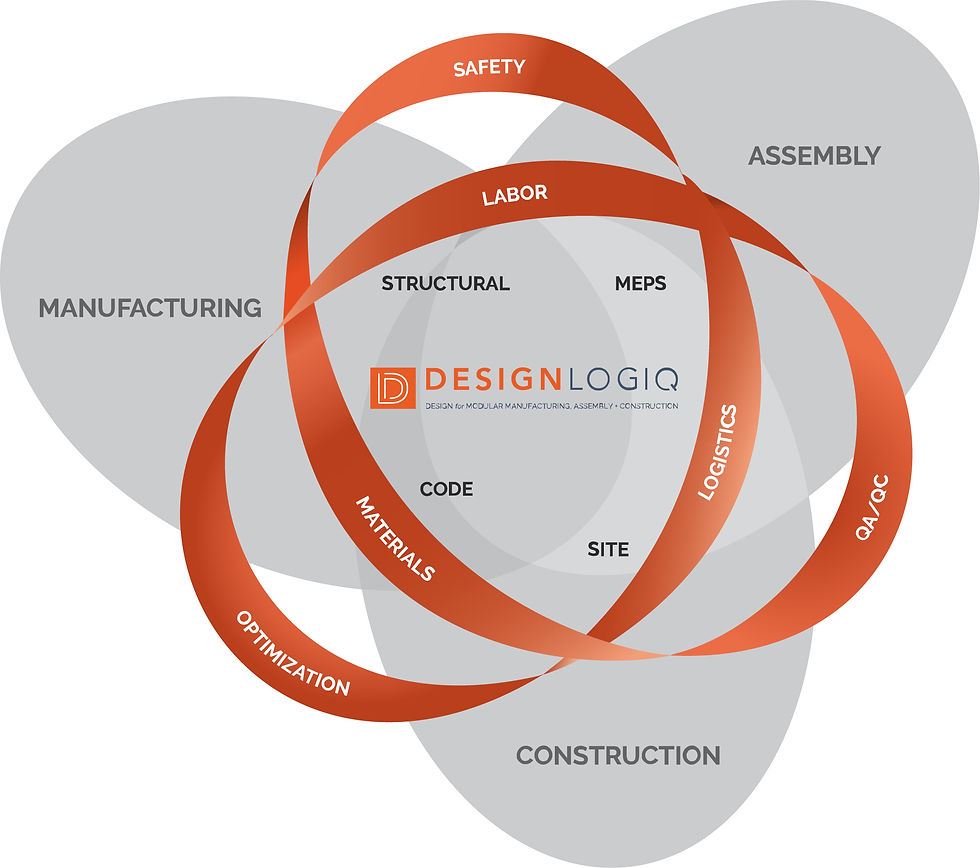

Q. What is DMMA+C?

A. DMMA+C = Design for Modular Manufacturing, Assembly + Construction. It extends the efficiency principles of Design for Manufacturing and Assembly by incorporating the Construction phase of modular projects. It's a holistic, systems-based design methodology that integrates all disciplines simultaneously from project start. This synergistic approach optimizes speed and efficiency in the design phase—as well as the manufacturing, assembly, and construction phases. The result is game-changing efficiency, unprecedented functionality, stunning aesthetics, and maximum ROI for your modular project.

Do you have a question about DESIGNLOGIQ? Drop us a line and let us know what's on your mind!

Comments