What is DMMA+C? (Design for Modular Manufacturing, Assembly + Construction)

- STAFF

- Dec 28, 2022

- 2 min read

Updated: Mar 16, 2023

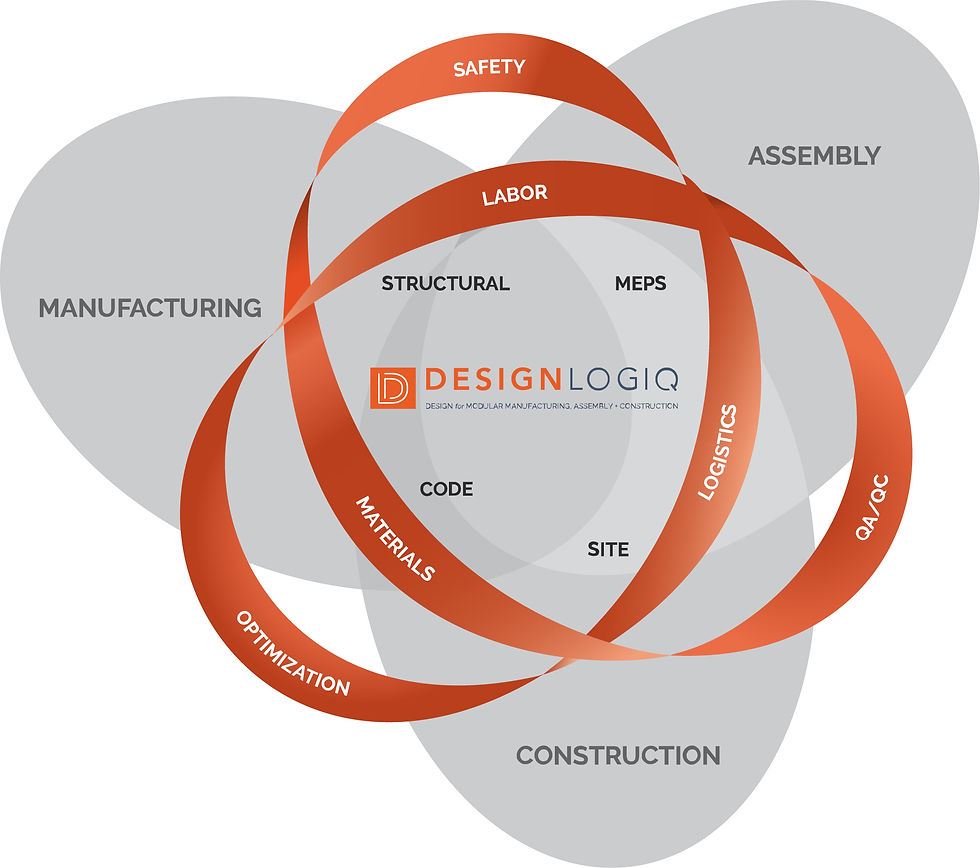

There are hundreds of ways to optimize the modular manufacture of a building across all phases of construction. DMMA+C is the holistic, systems-based design process that maximizes all factors from the very start of a modular project—architectural, modular, structural, engineering, safety, MEP, code, fabrication, transport, installation, site completion, and more.

Modular delivers important benefits: budget certainty, higher quality, greater sustainability, and faster openings with the least amount of operational disruption. DMMA+C maximizes those benefits across all phases of construction to deliver unprecedented functionality, stunning aesthetics, and maximum ROI.

Preconstruction. DMMA+C's holistic approach emphasizes decision-making early in the process to achieve up to 50% faster design cycles than with conventional design.

Design Consulting. DesignLOGIQ provides Consulting Architect services to help prevent compromises or issues from being inadvertently designed into a project.

BIM. DMMA+C capitalizes on the latest technology to ensure that the modular design can be efficiently manufactured, assembled, transported, installed, and completed at the site.

Engineering/Structural. DMMA+C addresses the unique issues of modular manufacturing, for example, the challenges that transport poses to the integrity of windows, doorways, facades, etc.

Strategic Sourcing. DMMA+C amplifies the supply chain efficiencies that are realized by manufacturing at a centralized plant while simultaneously delivering significant sustainability advantages.

Framing. DMMA+C takes greater advantage of modular and panelization techniques that increase quality, reduce framing time, improve structural integrity, etc.

Mechanical, Electrical, Plumbing (MEP). DMMA+C leverages BIM, 3D design, and clash detection tools to maximize overhead clearances in modules and ensure safe transit through tunnels and bridges with height restrictions.

Fixtures, Furnishings, and Equipment. DMMA+C calculates the advantages of installing at the factory versus installing at the site and then optimizes the build plan to achieve the best balance of savings and speed

Logistics. DMMA+C considers a logistics plan to reduce transport costs, significantly speed installation, and reduce site and environmental impact.

Installation. DMMA+C optimizes staging/scheduling, transport logistics, site installation, subcontractor/trades utilization, and more to accelerate installation and minimize operational/site impact.

Completion. DMMA+C evaluates all options to determine best mix of plant completion versus site completion while organizing site completion components for fastest finishing and smoothest system connections/re-connections.

About DesignLOGIQ

DesignLOGIQ was founded by modular manufacturing experts who have fabricated and delivered more than 200 permanent modular projects. Manufacturing is in our DNA. That off-site construction experience, knowledge, and expertise is the engine that drives our industry-changing Design for Modular Manufacturing, Assembly + Construction (DMMA+C). DMMA+C provides end-to-end confidence for custom modular projects—from feasibility studies to initial concept to modular design to fabrication to installation to completion to final Certificate of Occupancy. Our modular design expertise and the benefits of DMMA+C extend to all the sectors that can most profit from modular solutions: K-12, education, healthcare, higher ed, hospital/medical center, retail, and student housing, as well as emerging sectors like ghost kitchens, pop-up shops, permanent free-standing offices, and more. Visit www.DesignLOGIQ.com

Comments